Hardware Design

The Electronics design team has got expertise in High speed Electronics, Analog as well as mixed signal , Microprocessor and micro contrlollers, RF and High frequency as well as Power Electronics. The proven basic building blocks make it easy and faster to come up with new designs. The team is well aware of the complexities associated with Optoelectronic controls, thermal aspectas well as signal integrity. All the designs are done taking into account the life expectancy of the components,ESD and EMI/EMC requirements.

Firmware Development

The expertise in embedded system covers requirement analysis, specification development and implementation, integration of embedded software, application and system programming, graphical user interface as well as interface and protocol development. The team is fully conversant with the state of the art chips, and coding is done as per the industry standards. The developed firmware ndergoes rigorus independent testing before release.

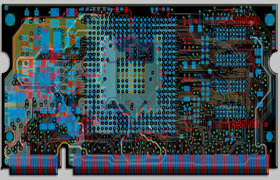

PCB Layout Design

Our PCB design teams have specialized Engineers who are well experienced in providing Engineering data preparation services for the global PCB industry. We act as a seamless extension to your in-house facility. As your process partner, we have the size, the technical resources and the experience to learn fast your requirement, to work closely with your in-house staff, and to deliver the job accurately and on time.

PCB design team works with clients across the globe addressing solutions for highly complex PCB design solutions meeting IPC specifications. PCB Engineering solutions include High Speed PCB Design, SI Analysis (Time Domain and Frequency Domain analysis), EMI/EMC and Reliability Analysis. The design team is well experienced in handling multi layer, complex and dense circuits. The Design for manufacturability as well as design for testing are taken care in the design itself, so that there shall be a smooth transfer to manufacturing.

Assembly & Production

The SMT line combined with Electronic board assembly facility at Vinvish makes it a destination for medium volume PWA manufacturing destination at the best speed. The manufacturing process follows ISO 9001:2000 as well as ISO13485 standards and procedures. The facility is also certified for ESD20:20. There are controlled environment chambers to store special components and the manufacturing facility is ESD protected.

Optics

This is one of the core team at Vinvish and the team comprises of several PhD and Master degree holders in Optics and optoelectronics. Modeling of classical optical components and simulation of systems make it easy for optical system designs. The clean optical lab is well equipped with state of the art equipment like Vibration table, Optical Spectrum Analyser, Optical sources, Precision alignment stages and drivers, Power meters, Special purpose splicing equipments, etc.

Mechanical Design

Mechanical design team uses AutoCAD as well as Solidworks CAD tool to design mechanical components and systems. The analysis done are tolerance analysis, Finite Elemement analysis, thermal analysis, etc. 2D as well as 3 D drawings are created for further manufacturing.

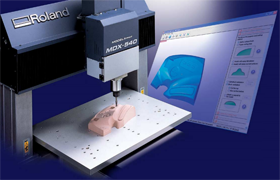

Rapid Prototyping

Clients want to see their product created within less time and in small numbers. This shall continue with a few iterations, till the final stage is reached. Vinvish has set up a Rapid prototype facility to cater to the above need. The rapid electronics board assembly as well as the precision bench top milling machine helps in making the enclosure as well as the board at a rapid scale.

- Various types of materials can also be used for the enclosure.

- Precision benchtop milling machine produces high-quality parts and models using Roland’s Subtractive Rapid Prototyping (SRP) technology.

- Cutting area of 500 mm (X)x 400 mm (Y)x 155 mm (Z) (19.6 (X)x 15.7 (Y)x 6.1 (Z) in.) accommodates larger prototypes.

- Advanced software optimizes 3D CAD data for flawless molds and parts.